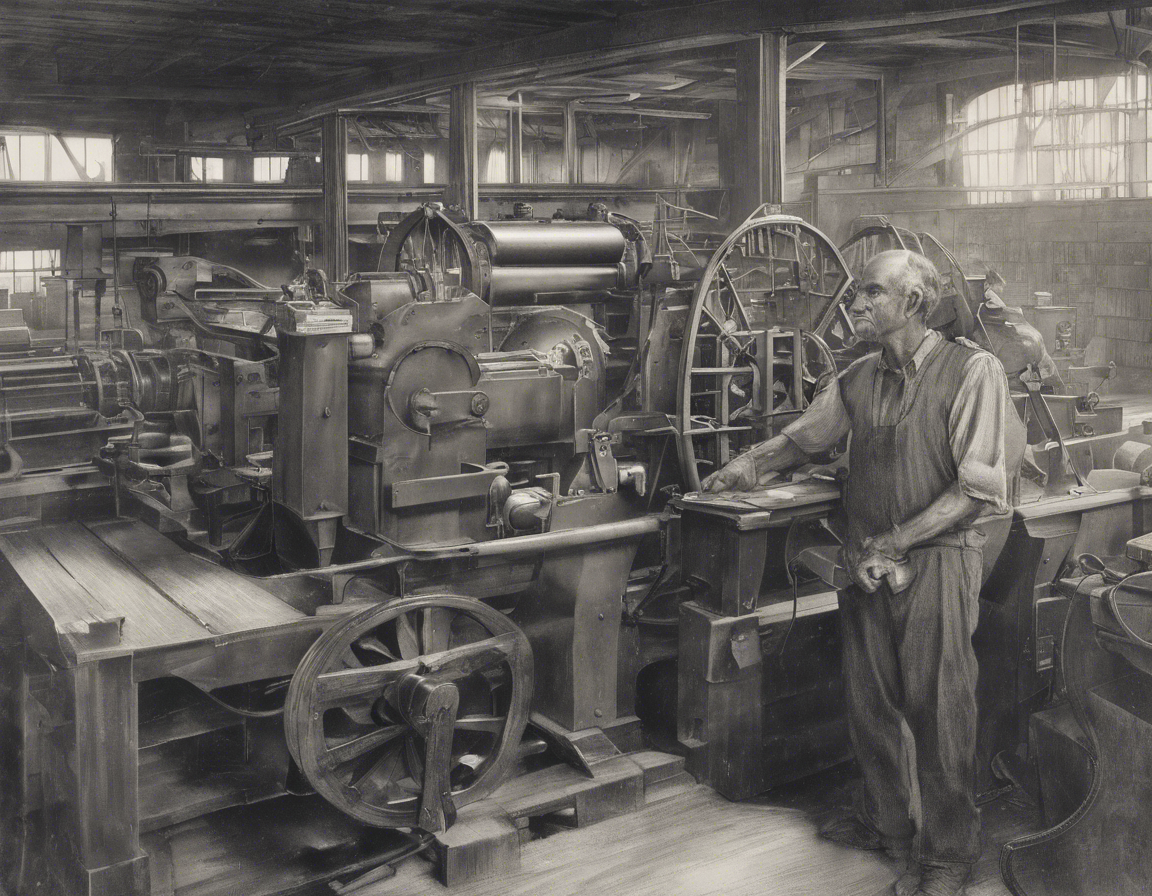

Mill workers play a crucial role in the manufacturing industry, contributing to the production of textiles, paper, lumber, and other materials. Working in a mill can offer stable employment and opportunities for career growth. However, before embarking on a career as a mill worker, it is essential to understand the eligibility criteria and requirements for this role. In this article, we will delve into the qualifications needed to become a mill worker, including education, skills, and other important considerations.

Education Requirements

To qualify as a mill worker, most employers require a high school diploma or GED equivalent. While a formal education may not be mandatory for all positions within a mill, having a basic level of education demonstrates essential skills such as literacy, numeracy, and problem-solving abilities. Some specialized roles within a mill, such as engineering or management positions, may require higher education qualifications such as an associate or bachelor’s degree in relevant fields.

Skills and Abilities

Technical Skills

- Machine Operation: Proficiency in operating machinery commonly used in mills, such as saws, lathes, or CNC machines.

- Maintenance Skills: Basic understanding of equipment maintenance and troubleshooting to ensure smooth operations.

- Safety Protocols: Knowledge of safety procedures to prevent accidents and ensure a secure working environment.

Physical Abilities

- Physical Stamina: The role of a mill worker often involves standing for long periods and lifting heavy objects, requiring good physical endurance.

- Manual Dexterity: Precise hand-eye coordination and manual dexterity are essential for handling machinery and materials effectively.

Experience

While some entry-level positions in mills may not require prior experience, having relevant work experience can be advantageous when applying for higher-level roles or specialized positions. Experience in manufacturing, construction, or other related fields can demonstrate practical skills and knowledge that are transferable to a mill environment.

Licensing and Certifications

Depending on the specific requirements of the mill and the nature of the work involved, certain certifications or licenses may be necessary. For example, operating forklifts or other heavy machinery may require certification to ensure safety and compliance with regulations. Employers may provide training for obtaining these certifications, or individuals may pursue them independently through accredited programs.

Additional Considerations

Shift Work

Many mills operate on a 24/7 schedule, requiring employees to work in shifts that can include nights, weekends, and holidays. Prospective mill workers should be prepared for non-traditional working hours and overtime as needed.

Teamwork and Communication

Effective communication and the ability to work collaboratively with colleagues are essential skills for mill workers. The mill environment often involves teamwork to meet production goals and ensure smooth operations.

Safety Awareness

Working in a mill can pose certain hazards, including exposure to heavy machinery, loud noise, and potentially hazardous materials. Maintaining a strong commitment to safety protocols and awareness of potential risks is crucial for all mill workers.

In conclusion, qualifying as a mill worker requires a combination of education, skills, experience, and a commitment to safety and professionalism. By understanding the eligibility criteria outlined above and preparing accordingly, individuals can position themselves for a successful career in the manufacturing industry.

Frequently Asked Questions (FAQs)

1. What are the opportunities for career growth for mill workers?

Mill workers can advance to supervisory roles, such as team leads or department managers, with experience and demonstrated leadership skills.

2. Do mill workers need to undergo background checks for employment?

Background checks may be conducted by employers to ensure the safety and security of the workplace, especially in environments handling sensitive materials.

3. Are there apprenticeship programs available for aspiring mill workers?

Some mills offer apprenticeship programs to provide hands-on training and mentorship for individuals looking to enter the industry.

4. What are the typical work hours for mill workers?

Work hours can vary depending on the mill’s operating schedule, with shifts commonly including day, night, and weekend rotations.

5. How can mill workers stay updated on safety regulations and best practices?

Employers often provide regular training sessions on safety protocols, and mill workers can also seek additional certifications or courses related to workplace safety.